There’s a space in the center stack of my 1991 Mitsubishi Montero that could be more useful than it is right now. It’s a little cubby spot, below another cubby spot, below the radio. Some wise individual out there has already discovered a better use for this space, and they’ve done so thanks to the magic of 3D printing.

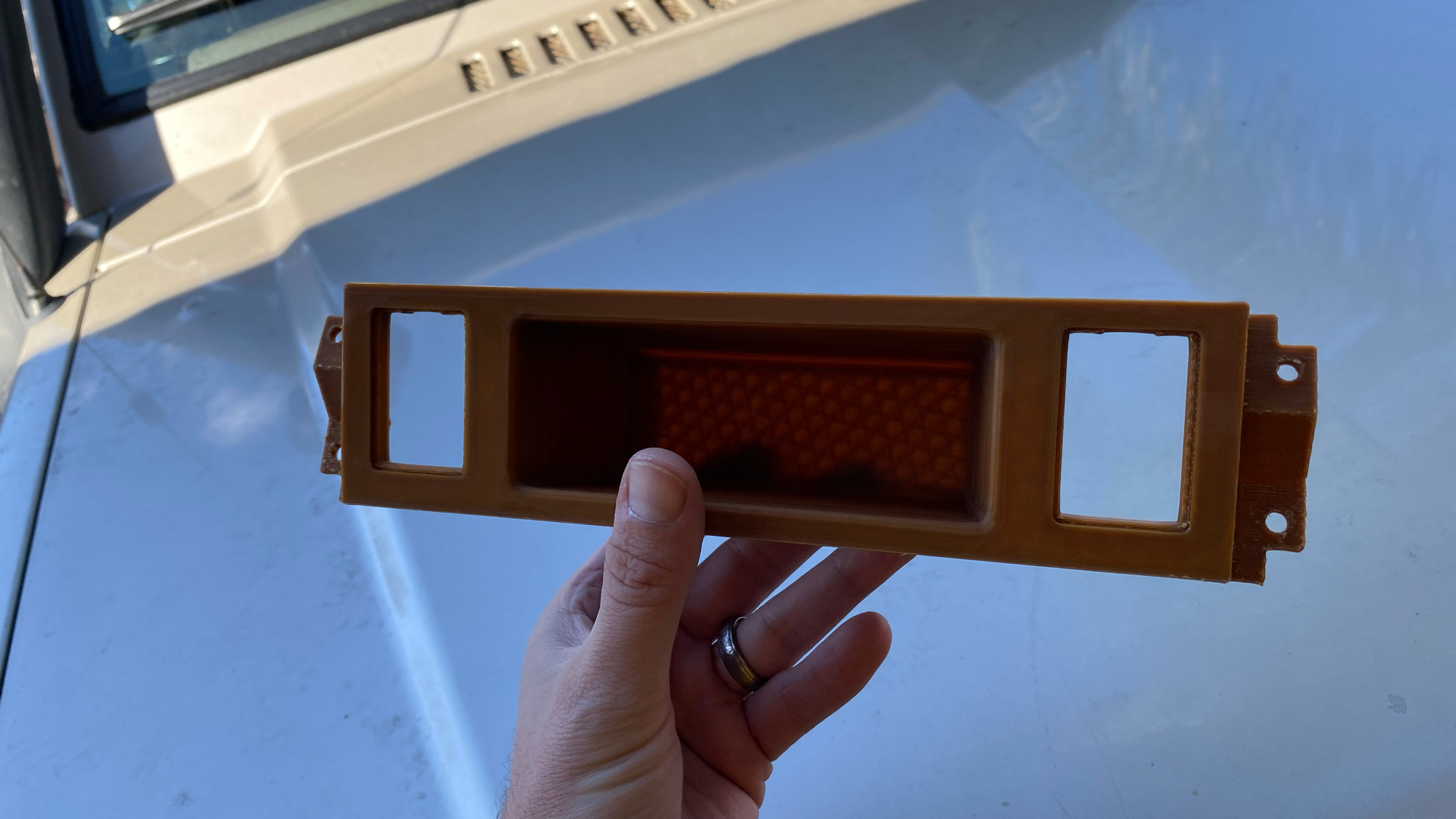

Do you see that lower section in the image above? The spot where the switches sit is typically just blank plastic. Now, you could obviously cut into that piece to make holes for switches if you need to. But I think it’s pretty fun to try out a 3D-printed part. So I had my friend Derek, who has already 3D printed parts for a Subaru Forest project car he owns, fire up his machine and see what he could do.

The part, while not a perfect color match, fits perfectly. And those slots will soon be home to a pair of switches for some coming goodies for the Montero. Additionally, I have the original piece still too. So if I eventually dislike the color difference, I can always hack up the original part using this 3D printed piece as a template. Or simply paint the 3D printed piece to get it to be a closer match to my interior poo hue.

As far as the printing goes, it took a few hours for each piece. This was printed in two sections as Derek deemed the best use of materials and likelihood of final product success. And he was right. The piece looks and feels great.

Now, what else can we come up with for cool 3D-printed parts?

Leave a Reply